Rubber Tracks - Ground Conditions & Use

DIGBITS have specialised in the supply of rubber tracks since 1991. Our mini excavator rubber tracks come with a manufacturer’s warranty*:

- Camso SD rubber tracks; 24 month/2000 hours manufacturer's warranty*

- Camso HXD rubber tracks; 36 month/3000 hours manufacturer's warranty*

Bear in mind that many excavator manufacturers do not cover tracks in their warranty schedule, and are therefore very unlikely to cover replacement/second fit tracks.

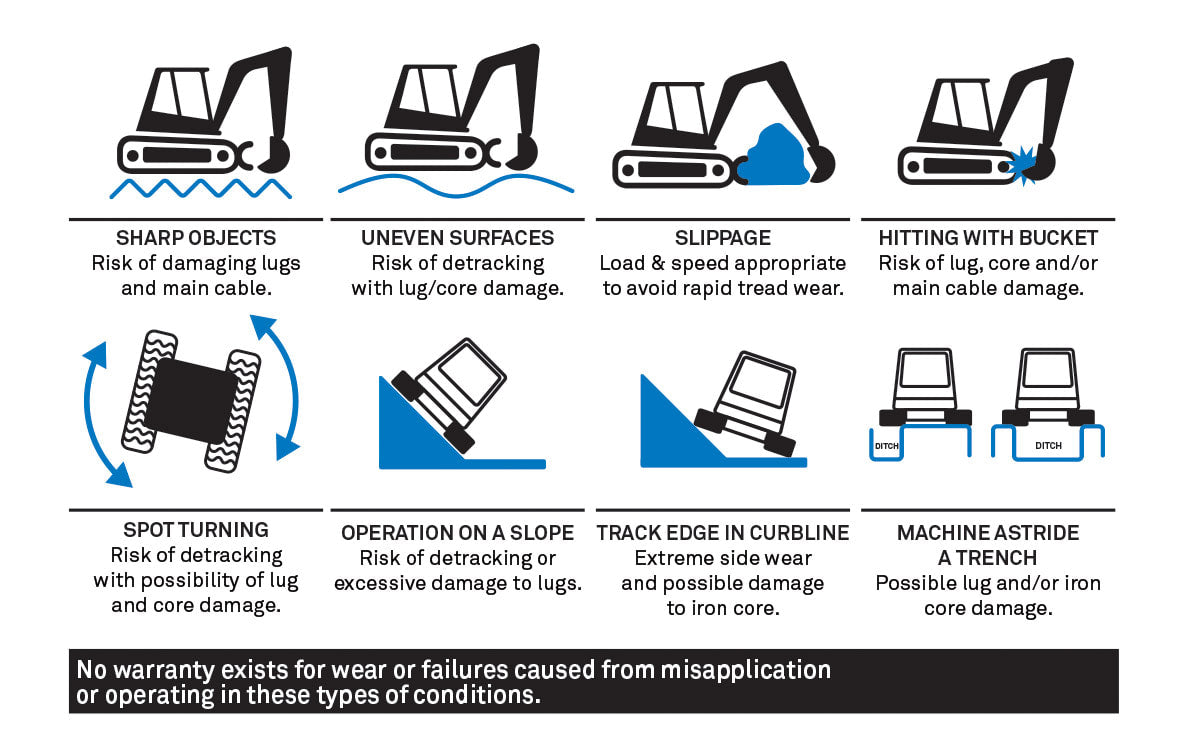

However, even our warranty does not include for abuse, only manufacturing defects. Observing the guidelines in this section will help ensure you get the longest, safest service from your new rubber tracks.

*This does not apply to skid steer loader tracks, and machines have a travel speed over 3 mph, where the warranty is 500 hours, or six months. See product page for further information.

Camso MEX SD and MEX HXD

mini-excavator: high performance rubber tracks