Digbits Engineering

|

DIGBITS Engineering, Key Point, Rugeley, Staffordshire.

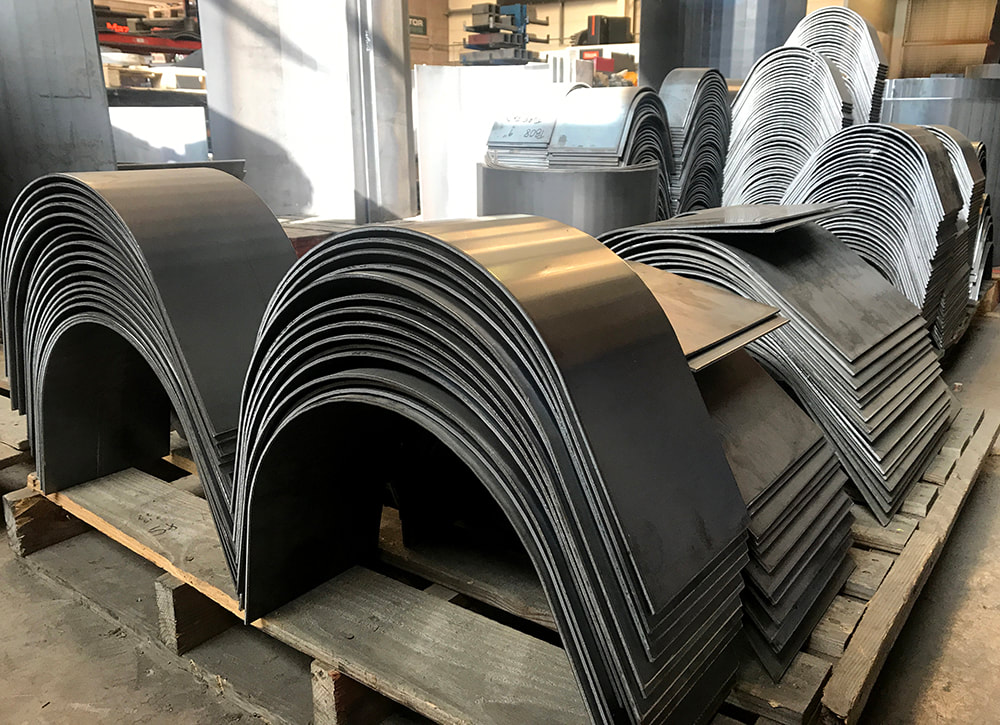

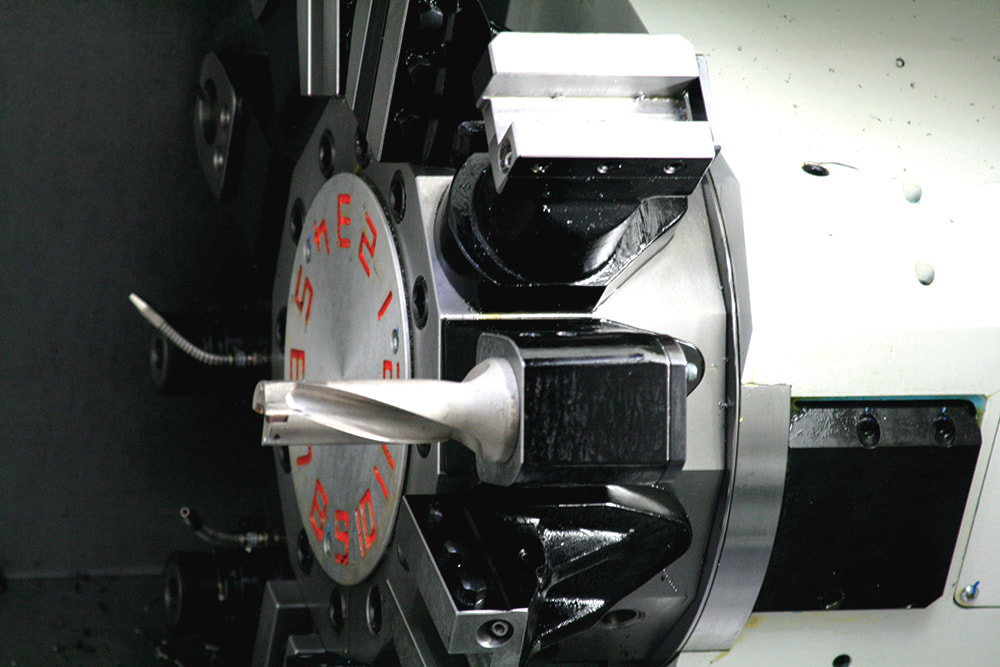

Production began at Key Point, Rugeley in 25 May 2007. Click for Plant List. Main product lines are:

|

British Engineering:

The trend for outsourcing manufacturing to low labour-cost overseas suppliers, such as the Far East and Eastern Europe, has seen the failure of many British engineering firms. The demise of many of our own, valued sub-contractors was key to our decision to establish our own, in-house engineering division in 2005.

DIGBITS has long recognised the benefits of utilising overseas resources for high volume, high labour content product - such as our rubber track supply - but we also understand their limits.

DIGBITS has long recognised the benefits of utilising overseas resources for high volume, high labour content product - such as our rubber track supply - but we also understand their limits.

The right kit for your job:

When we established our Engineering division, the philosophy was to augment our substantial sales stock of equipment - buckets and attachments - with the ability to react to customer demand for special, custom built equipment. We wanted the ability to offer customers the correct kit to get their work done quickly and efficiently, rather than simply try to sell whatever we happen to have in stock.

Problems for Imports:

We could not have achieved the service we wanted to offer with a 2-4 day road freight delay from Eastern Europe, let alone a 4-6 week shipping time from the Far East.

There are also environmental issues involved. BP estimates current annual CO2 emissions from shipping at between 600 and 800 million tonnes. Put this in context, roughly double the entire UK's total emissions. This will not avoid environmental taxes for long and coupled to rising congestion and cost on UK container handling, the tide may turn in favour of UK manufacturers.

There are also environmental issues involved. BP estimates current annual CO2 emissions from shipping at between 600 and 800 million tonnes. Put this in context, roughly double the entire UK's total emissions. This will not avoid environmental taxes for long and coupled to rising congestion and cost on UK container handling, the tide may turn in favour of UK manufacturers.

Quality:

Having tested production overseas, we have also identified difficulties in getting the exact specification of raw materials for fabrications. Even where the quailty is available, differences in classification codes and systems bring potential for confusion which can ultimately be costly to the end user.

So give us a try:

We think you'll be pleased you did. We retain many customers who dealt with us in our first years of trading, since 1991. Just as importantly, customer recommendation is still our biggest single source of new business, so we must be doing something right.