TECHNICAL RESOURCE

Rubber Tracks - Changing a rubber track

Follow the general guidlines below to fit a replacement rubber track:

- First park the excavator on firm, level ground.

- Next swing the machine round and push up with the bucket to raise the track off the ground.

- Before proceeding further put wooden chocks under the excavator to prevent it dropping in case of a mechanical or hydraulic failure. Then switch off andremove the ignition key.

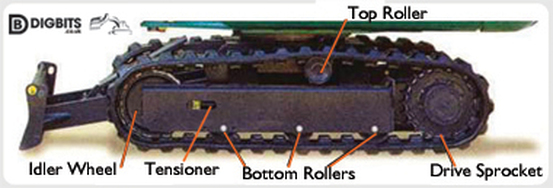

- Next reduce track tension by removing the grease nipple (see tensioner on diagram) and pushing the idler wheel into the track frame assembly, to exclude the remaining grease.

- Remove old track, checking that the new track is the correct size.

- Fit new track, normally this is easiest done by putting sprocket end on first, then the idler wheel end.

- Replace grease nipple and re-tension the track, as detailed in the ‘Tensioning’ section, using your grease gun.

- Before removing the timber and lowering the machine to the ground, check that other under carriage components are not worn and in danger of reducing the life of the new track.

The videos below provide further explanation: