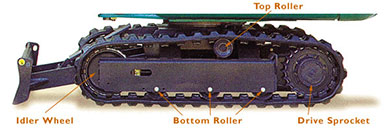

Undercarriage Parts

DIGBITS manufacture and stock undercarriage components and spare parts for most popular makes and models of micro, mini and midi excavators, alongside a full range of rubber tracks.

|

Sprockets in particular, should ideally be replaced whenever new tracks are fitted to ensure they are of the correct pitch and will mesh properly. This is particularly true on rubber tracks, which rather than wearing the teeth down, tend to wear the dwell between the teeth, down towards the sprocket centre. This type of wear damages tracks since it causes an effective reduction in the sprocket pitch, and an increase in tooth height.

|

Bottom rollers should generally be replaced either as a whole machine lot, or at least one track frame at a time, since fitting a single new roller alongside worn items, will result in the new item bearing too much load, causing premature failure.

Any worn, seized, or loose components can cause damage to tracks and track motors due to increased drag and may also cause premature failure of rubber tracks due to sprocket damage to the core wires as a result of de-tracking. |

Track Rollers:Undercarriages are designed so that the Bottom Rollers bear the weight of the machine, whilst Top Rollers (where fitted) guide the track over the frame. Worn rollers should be replaced to prevent damage to other undercarriage and drive components.

|

Idler Wheels:For tensioning and guiding the track around the front of the undercarriage frame. Worn or seized idlers will create drag and can result in severe damage to tracks and undercarriage due to frequent de-tracking.

|

Drive Sprockets:Available for most popular mini & midi excavators from 0.75 to 7 tonnes, most are bolt on type. Vital for good track life, these should normally be replaced when fitting new rubber tracks.

|