TECHNICAL RESOURCE

Rubber Tracks - Tensioning

The correct tension for a 1.5 tonne mini excavator is normally about 10-15mm up and down movement in the middle, but can be greater for larger excavators. These figures give a rough guide:

1.0 to 1.9 tonne minis 10-15mm

2.0 to 2.9 tonne minis 30-35mm

3.0 to 5.0 tonne minis 40-45mm

Re-check and adjust the tension after and hour or so of operation, not least because this is unfortunately the most common time for the idler adjuster seals to fail.

Avoid over-tensioning tracks. Aside from causing unneccesary wear and friction on the drivetrain, pumping excessive pressure into the idler grease adjuster will cause the seals to fail.

1.0 to 1.9 tonne minis 10-15mm

2.0 to 2.9 tonne minis 30-35mm

3.0 to 5.0 tonne minis 40-45mm

Re-check and adjust the tension after and hour or so of operation, not least because this is unfortunately the most common time for the idler adjuster seals to fail.

Avoid over-tensioning tracks. Aside from causing unneccesary wear and friction on the drivetrain, pumping excessive pressure into the idler grease adjuster will cause the seals to fail.

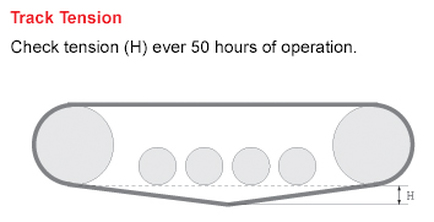

Routine Checks

Check track tension every 50 hours:

- Too slack, and the track may come off whilst turning in soft ground.

- Too tight and hard stones carried round on to the sprocket may split the track.