TECHNICAL RESOURCE

Rubber Tracks - Sizes

It used to be possible to identify track from just three key dimensional features;

- Width – the overall tread width of the track

- Pitch the spacing between the centres of the metal inserts (track links)

- Links - the number of metal inserts or links in the track

e.g. 230x072x42 = 230mm wide, 72mm pitch, with 42 links

However, as track and undercarriage technology has evolved, there are other key criteria to be identified.

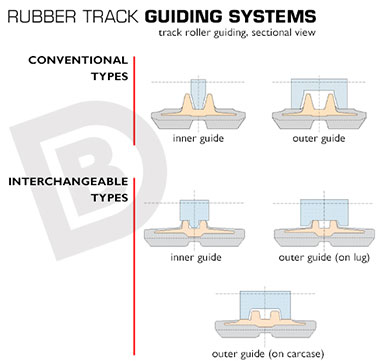

Track inserts can be designed to mesh specifically with different types of rollers.

Tread types are also factor.

Hence, the plain old 230x072x42 track has now become (in our full size designation) a 230x072x42 XAR.

|

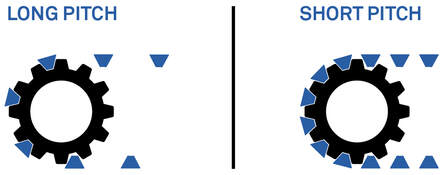

Long Pitch and Short Pitch design is another variable. Briefly, the latter is the newer type and has been developed to reduce tracking vibrations and better resist de-tracking, which can cause severe damage to tracks.

The difference is easy to spot, once you look closely - the short pitch design has twice as many metal inserts, so they mesh with every single tooth on the drive sprocket, rather than every other. |

Not all manufacturers like to put the full (or even partial) information onto their tracks, which is why, to be safe and ensure we offer you the correct tracks, we’d usually prefer to know the exact make and model of machine when we are quoting you. We have a database covering thousands of machines (and increasing) to ensure you get the right tracks.

Due to the growing complexity of track systems, getting the wrong tracks is not always immediately apparent. We have heard stories of our companies offering tracks which ‘will fit’, often at a peculiarly low price, only for them to fail within 12 months.

When you consider the potential damage to other undercarriage components, the cost and inconvenience of unnecessary site visits for your fitter, and the upset for your customers, is it really worth saving a few pounds on a track?

If we are not sure our tracks will fit your machine, we will tell you, and also advise you that (even though they may be more expensive) it may be worth buying the genuine parts in this instance.

If you know the make and model of excavator your have, you can find out which track fits here: Camso Track Finder

Due to the growing complexity of track systems, getting the wrong tracks is not always immediately apparent. We have heard stories of our companies offering tracks which ‘will fit’, often at a peculiarly low price, only for them to fail within 12 months.

When you consider the potential damage to other undercarriage components, the cost and inconvenience of unnecessary site visits for your fitter, and the upset for your customers, is it really worth saving a few pounds on a track?

If we are not sure our tracks will fit your machine, we will tell you, and also advise you that (even though they may be more expensive) it may be worth buying the genuine parts in this instance.

If you know the make and model of excavator your have, you can find out which track fits here: Camso Track Finder